Km Series Hypoid Gearmotors Worm Gear Km Hypoid Reducer

As one of the worm reducer manufacturers, suppliers, and exporters of mechanical products, We offer worm reducer and many other products.

Please get in touch with us for details.

Mail:[email protected]

Worm Reducer

Worm reducers are a type of gear reducer that uses a worm gear and a worm wheel to transmit power between two shafts. Worm gears are spiral-shaped gears that mesh with worm wheels, which are gear wheels with teeth that are perpendicular to the axis of the wheel.

Worm reducers are known for their high torque capacity, low noise levels, and smooth operation. They are also very efficient, with efficiencies of up to 98%. This makes them ideal for a wide range of applications, including:

- Industrial machinery

- Agricultural equipment

- Construction equipment

- Mining equipment

- Food processing equipment

- Material handling equipment

- Automated manufacturing equipment

- Robotics

Advantages of Worm Reducers

Worm reducers offer a number of advantages over other types of gear reducers, including:

- High torque capacity: Worm reducers can transmit high torques, even with low input speeds. This makes them ideal for applications where high torque is required, such as lifting and moving heavy objects.

- Low noise levels: Worm reducers operate very quietly, making them ideal for applications where noise is a concern.

- Smooth operation: Worm reducers provide smooth and even power transmission, without any backlash or vibration. This is important for applications where precision is required.

- High efficiency: Worm reducers have efficiencies of up to 98%, which means that they waste very little energy. This makes them an energy-efficient solution for power transmission.

- Durability: Worm reducers are made of durable materials and are designed to withstand harsh operating conditions.

Types of Worm Reducers

Worm reducers are available in a variety of types, including:

- Single-worm reducers: Single-worm reducers are the most common type of worm reducer. They use a single worm gear to drive a single worm wheel.

- Double-worm reducers: Double-worm reducers use two worm gears to drive a single worm wheel. This provides even higher torque capacity and lower noise levels than single-worm reducers.

- Right-angle worm reducers: Right-angle worm reducers are designed to transmit power between two shafts that are at a right angle to each other.

- Inline worm reducers: Inline worm reducers are designed to transmit power between two shafts that are parallel to each other.

Selecting the Right Worm Reducer

When selecting a worm reducer, it is important to consider the following factors:

- Torque capacity: The worm reducer must have a torque capacity that is greater than or equal to the torque that is being transmitted.

- Speed ratio: The worm reducer must have the correct speed ratio to achieve the desired speed reduction or increase.

- Input and output shaft sizes: The worm reducer must have input and output shaft sizes that are compatible with the other components in the power transmission system.

- Mounting type: The worm reducer must have a mounting type that is compatible with the application.

- Service environment: The worm reducer must be made of materials that are suitable for the operating environment. For example, a worm reducer that will be used in a corrosive environment should be made of stainless steel.

We are one of the best worm reducer manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Factory tour

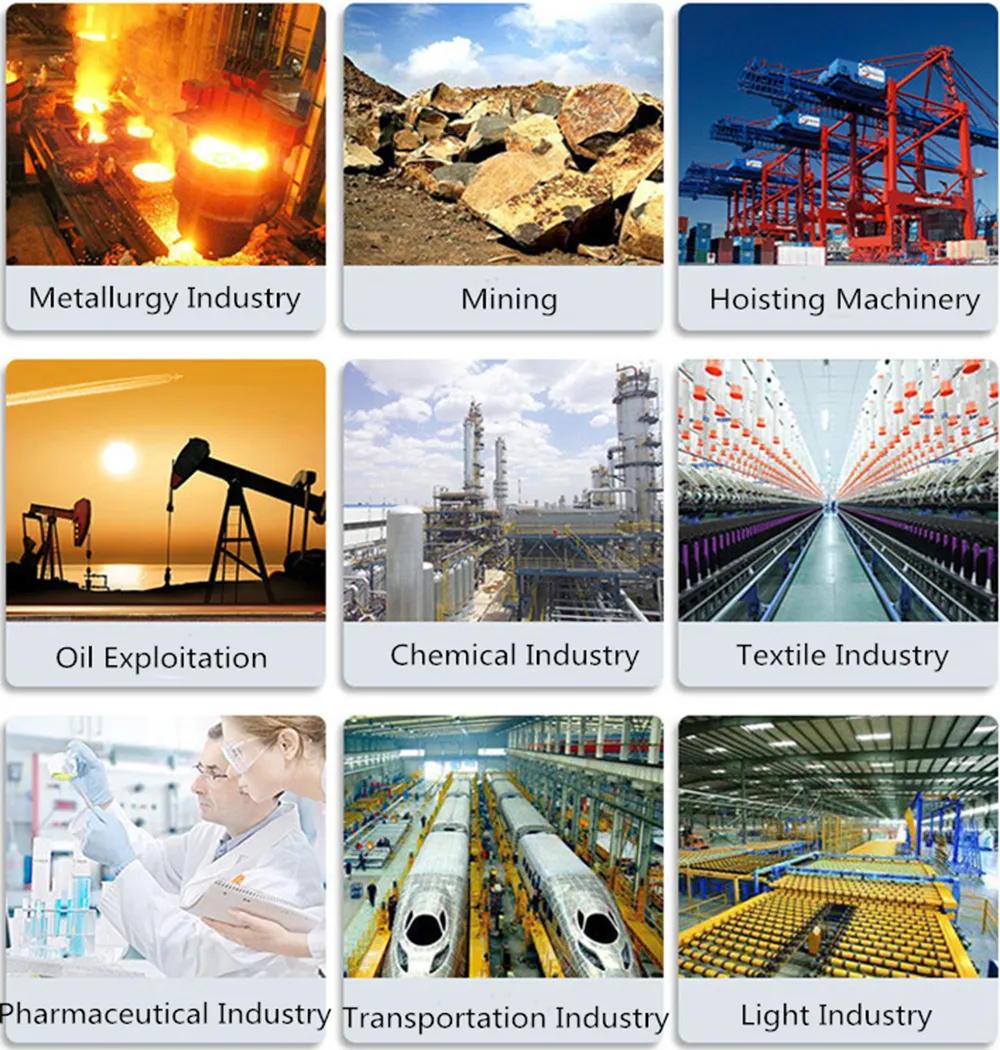

Application